A fellow Etsian asked me if my notebooks came ready made and I just added something to it. So, I think I should explain my process.

A fellow Etsian asked me if my notebooks came ready made and I just added something to it. So, I think I should explain my process.

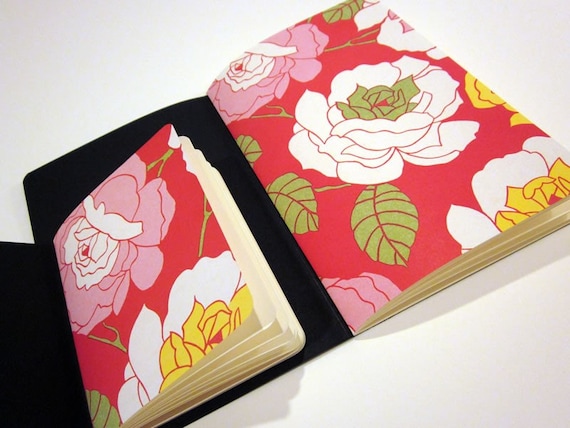

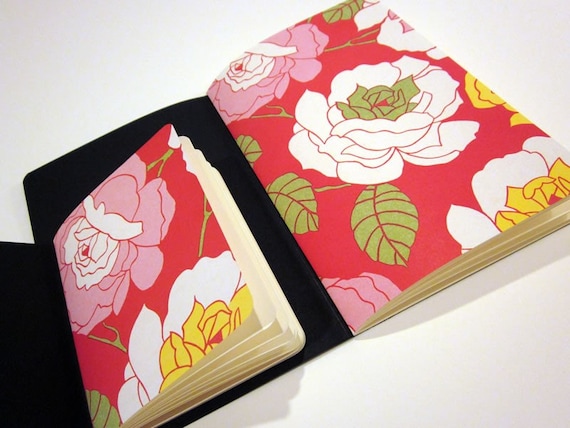

Before I go on, in my notebooks, you will usually find that the first/last inside page is different than the rest. I did that because I use them to as the place for the table of contents and notes. But if the design/purpose doesn’t call for it, then it will be the same as the rest of the inside pages.

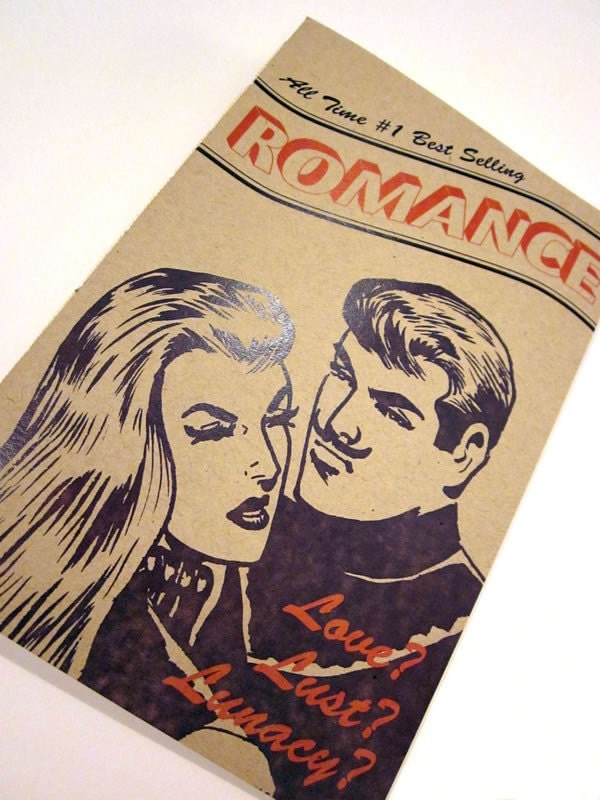

If I have a cover design in mind:

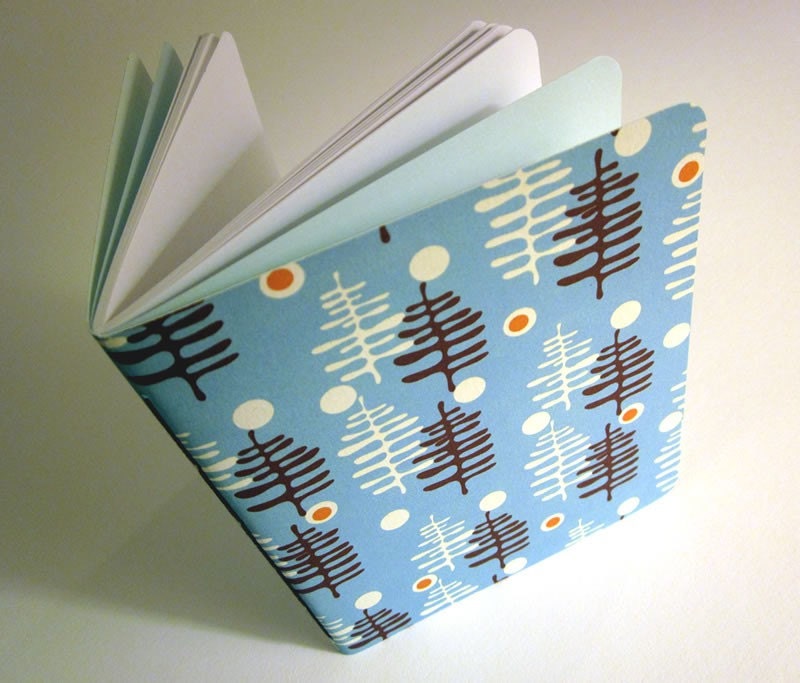

- I select a cover weight paper that fits with the design

- Print the design using my laser printer (so the design won’t fade by water droplets) but a few designs do require ink jet output.

- Select the first/last and inside pages to go with the cover

More Examples: “Your Way, Yes Way“, “Idea Reservoir”

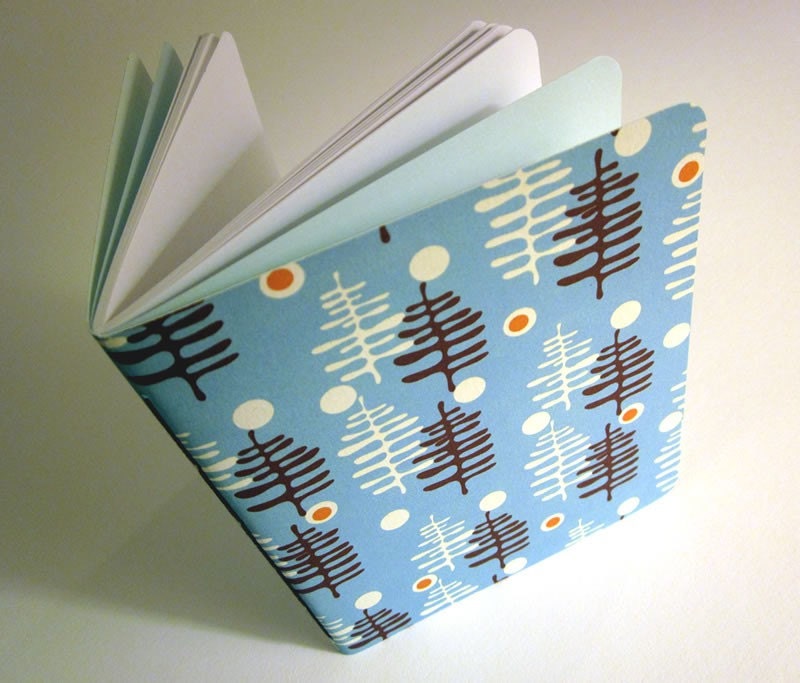

If I find paper with interesting pattern or texture, I’ll pick something different for the first/last page to go with the pattern or texture.

If I find paper with interesting pattern or texture, I’ll pick something different for the first/last page to go with the pattern or texture.

For the inside pages, I usually use quality white paper that is much more opaque than copier paper. If the design calls for it, I’ll use the color paper. In is case, the notebook might have less pages because color paper is thicker than the white paper.

Once the paper for the cover, first/last and inside page are collected, I use a color cotton thread that goes with the notebook, then hand stitched them together.

Once the paper for the cover, first/last and inside page are collected, I use a color cotton thread that goes with the notebook, then hand stitched them together.

The last step is to cut the notebook into the final size. And depending on the design, I decide to round the corners or not. Most of the time I do because straight cut corners tend to get bent.

I try my best to find materials that are made of recycled materials and/or can be recycled and often decides against designs that will make my products hard to recycle.

My last post on the book 59 Seconds by Richard Wiseman was on happiness. This time I was inspired by the chapter on creativity.

My last post on the book 59 Seconds by Richard Wiseman was on happiness. This time I was inspired by the chapter on creativity.